Production system with advanced automation and efficiency that supports the creation of high-quality products

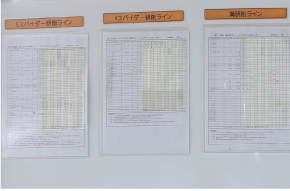

We will respond to the diverse needs of our customers with our production system that pursues manufacturing with high quality and cost-effectiveness, through the reduction of cycle time and saving space as well as introducing unmanned lines, etc. In addition, our entire company is involved in facility maintenance activities. By implementing maintenance and inspection on all equipment, based on a maintenance calendar, we realize manufacturing that is always stable.

Gear bush cutting line

Gear bush grinding line

Spider cutting line

Valve cutting line

Universal joint cup assembly machine

Zero lash adjuster assembly machine

Tensioner assembly machine

Small-diameter bearing processing line

Valve bore grinding line

Cup grinding line

Spider grinding processing line

Intermediate shaft line

Cup bore grinding line (Bryant grinder)

Maintenance calendar